EEC-F ECT sorting system is provided for hardness sorting, material sorting, and heat treatment sorting. It can be used for inspection and sorting of metal tubes, bars, wires, auto parts, valves and various metal components. The difference of structure, surface hardness, case depth can be well separated too.

EEC-F eddy current tester is specially used for inspection and sorting of metal tubes, bars, wires, auto parts, valves and various metal components. The difference of structure, surface hardness, case depth can be well separated.

EEC-F is designed with configuration analysis function. Since the mapping of electromagnetic characteristics of the same material on eddy current impedance diagram conforms to two-dimensional normal distribution, this equipment can automatically generate elliptical sorting area with adjustable X radius, Y radius and angle.

Parameters of EEC-F can be saved for next time use, and the sorting result can be save for print. The testing data can be saved in the hard disk.

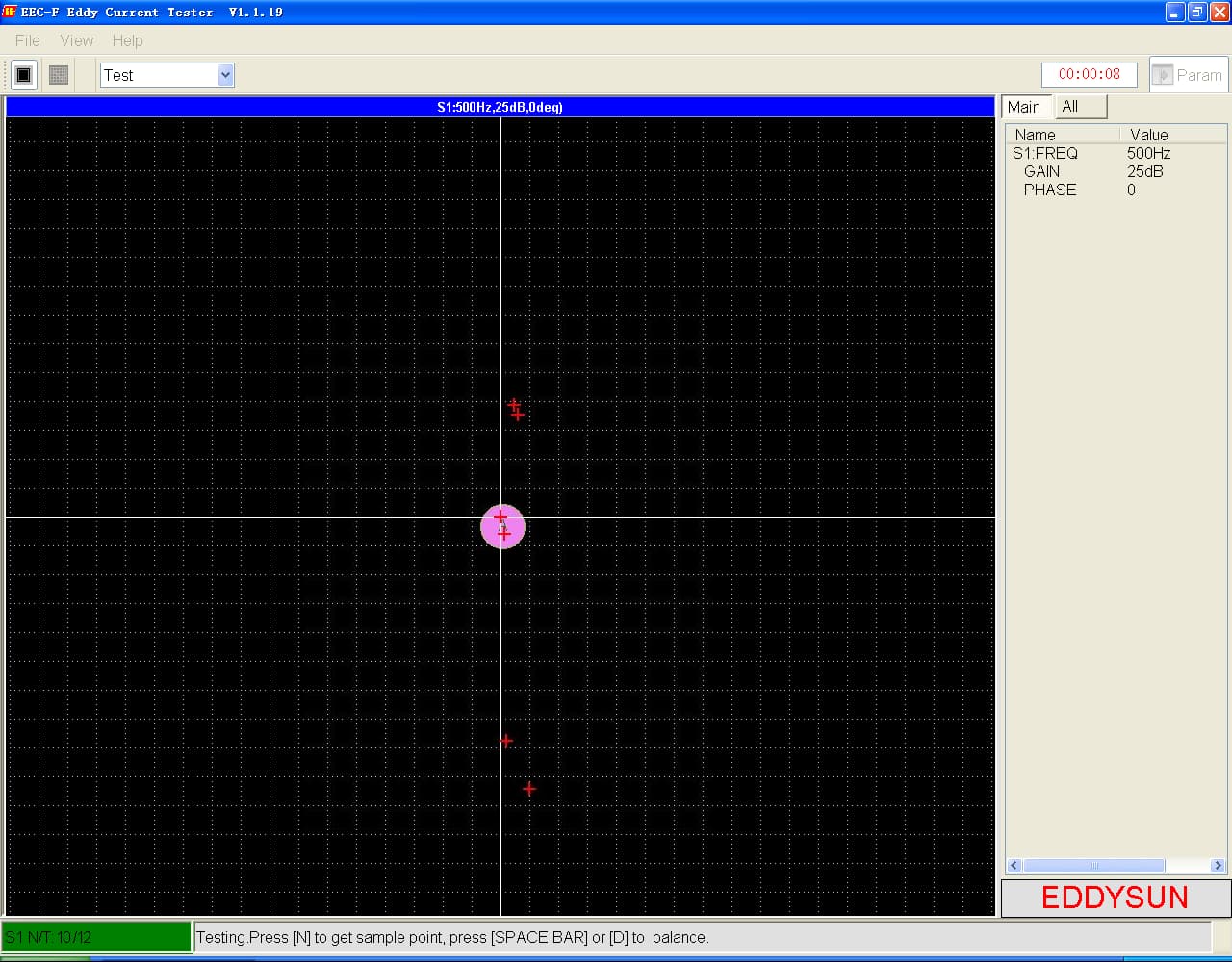

Testing display

Specifications

● Frequency range: 64Hz~5MHz

● One channel

● Range of gain: 0~90dB with step of 0.5dB

● Phase rotation: 0~359° with step of 1°

● Fast digital / analogue electric balance

● Impedance plan diagram

● Probe drive ranges from 1~8V

● Digital filtering

● Can match with absolute probe, differential probe, self-compared probe (such as encircling probe, pencil probe, flat probe, rotary probe etc.)

● 2 output ports of hardware alarm

● Big storage for testing program and testing data

● Automatically count the amount of work pieces be inspected and the defect number, and display on the screen while testing

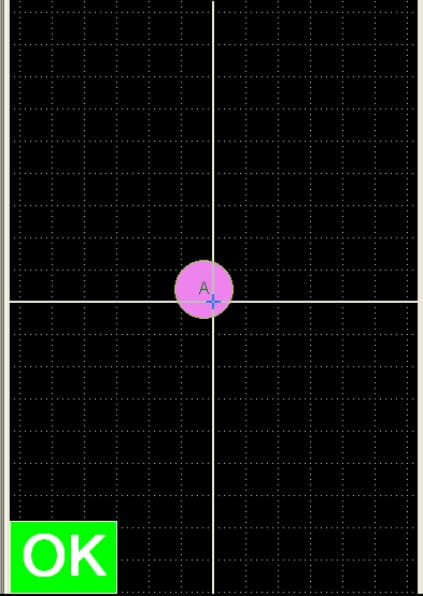

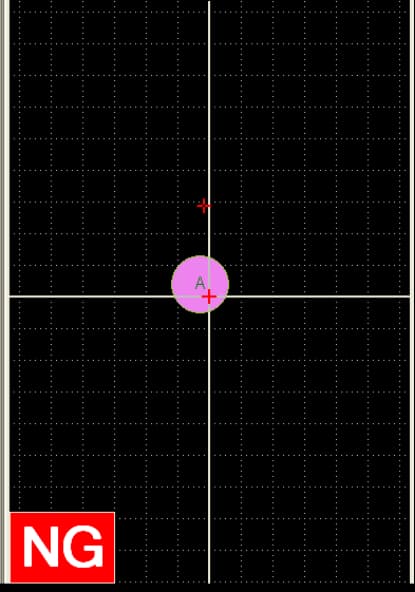

Sorting of OK part and NG part

Widely Used For

• ECT sorting system is provided for hardness sorting, material sorting, and heat treatment sorting

• Inspection of metal tubes, bars, wires, auto parts, valves and various metal components

• Sorting of structure, surface hardness, case depth for metal materials