Heat exchanger tube inspecton system with ECT and RFT functions for both ferrous and non-ferrous tubes. Mixing function enables noise signal remove from the support plate, and tube sheet mapping enables to draw the tube layout and to mark the testing result with different colors.

This powerful RFT/ECT instrument is designed with 2 channels, 4 frequencies, mixing unit and tube sheet mapping. It’s widely used for inspection of small pipeline, heat exchanger tubes and boiler tubes, for both carbon steel and non-ferrous materials.

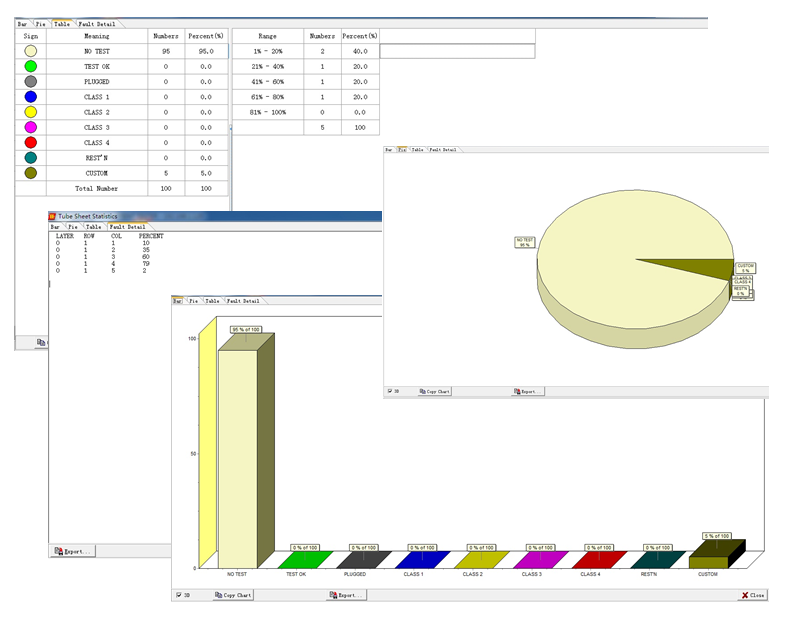

Tube sheet mapping draws the tube layout and marks the testing result with different colors. Mixing unit removes signal from support plate and leaves only defect signal. Inspection settings for different applications can be stored in files and simply called up when needed. And different types of report can be generated for analysis and record.

|

Specifications |

|

|

Application |

Defect detection, material/hardness sorting, wall thinning inspection etc. |

|

Channel |

2 channel |

|

Frequency |

4 frequencies per channel with 64Hz-5MHz for ECT, 5Hz-5KHz for RFT |

|

Mixing Unit |

mixing unit to suppress noise signal at a constant frequency |

|

Tube Sheet Mapping |

Tube sheet mapping draws according to real tube layout, and testing result is marked in different colors |

|

Calibration |

Calibration on known flaws and automatic generation of calibration curve. Calibration data can be saved and simply called up when needed |

|

Probe Type |

Differential, absolute, DP, encircling coil, pencil, flat, sector etc. |

|

Screen Display |

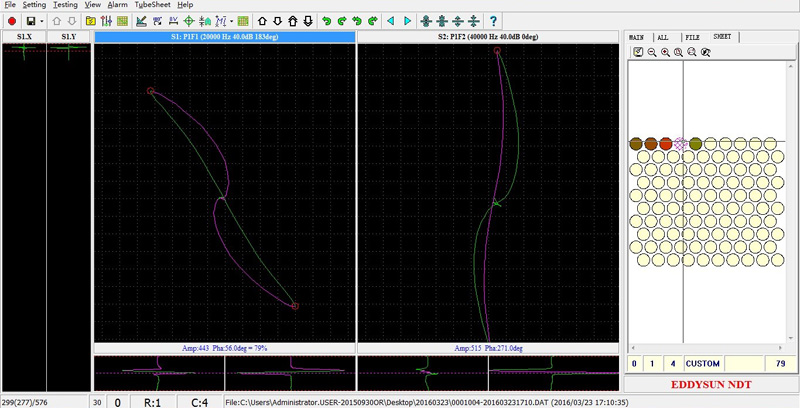

Real-time strip chart, impedance plane , tube sheet display |

|

Report |

Automatic generation of report in different format |

|

Alarm Output |

One hardware alarm output with triode OC gate |

|

Gain |

0-90 dB in 0.5 dB steps |

|

Phase |

0-359° in 0.1° steps |

|

Gain Ratio (Y/X) |

0.1-10 |

|

Impedance Display Mode |

Point, Line, Auto |

|

Filter |

High pass: 0-500 Hz; Low pass: 10-10000 Hz; Digital: 1-100 |

|

Drive Voltage Level |

1-8 levels |

|

Background Coordinate |

Rectangular coordinate, polar coordinate |

|

Power Supply |

Built-in lithium battery (14.8V, 5.7AH) for long working time per charge |

|

Storage |

Mass storage for testing data and parameters |

|

Balance |

Fast digital/analog electronic balance |

|

Language |

English and Chinese |

|

Operating Temperature |

-20°C to 55°C |

|

Instrument Dimensions |

2.0kg; 290mm x 210mm x 42.5mm |

Real-time strip chart, Impedance plane, Tube sheet display with color mapping

Different reports generated for record and further analysis.

Widely Used For

• Inspect carbon steel and non-ferrous heat exchanger tubes, small pipeline, boiler tubes

• Crack detection for aircraft components, auto parts, axles, machine parts, bolts and so on

• Surface inspection for welds with or without coating

• Sort different heat treatment conditions and different materials

|

MODEL |

CHANNEL |

FREQUENCY |

ECT |

RFT |

VIDEO |

TUBE SHEET |

|

EEC-39RFT++ |

8 |

8 for each channel |

√ |

√ |

√ |

√ |

|

EEC-39RFT+ |

8 |

8 for each channel |

√ |

√ |

× |

√ |

|

EEC-39RFT |

2 |

4 for each channel |

√ |

√ |

× |

√ |

|

EEC-39 |

2 |

4 for each channel |

√ |

× |

× |

√ |

|

EEC-35RFT |

2 |

2 for each channel |

√ |

√ |

× |

√ |

|

EEC-35++ |

2 |

2 for each channel |

√ |

× |

× |

√ |

Purchase Includes

EEC-39RFT instrument

Standard sample tube for instrument calibration

Standard inserted ECT probe for sample tube

Probe converter

Communication cable

Instrument case

Testing software backup

User manual & Quality certificate

One year warranty